Geotechnical audits – a versatile tool

Geotechnical audits – a versatile tool

Recently AMC has undertaken a number of geotechnical audits for companies in Africa, South America, Australia and Russia. These have been done for a number of reasons:

- as a tool to complement resource and reserve audits

- as a benchmarking tool to compare mining projects within a companies’ mining portfolio, and

- as a compliance tool for Ground Control Management Plans (GCMP).

Underpinning the audit process is a company’s aim to confirm that the geotechnical design process for an underground or open-pit operation is robust and conforms to accepted industry standards, and that these standards are being implemented. In addition, the audit process is able to compare the outcomes from this process across different mining operations. This can help to identify differences and in some cases gaps in a company’s overall approach.

Examples of leaders in the provision of geotechnical audit tools are jurisdictions within Australia, including New South Wales1 and Western Australia2 3.

It is important to understand that the audit process does not provide a detailed technical review of mine design components. The aim of the audit is to identify whether appropriate systems and standards have been established by the mine to address geotechnical aspects that are applicable to mine design, and these systems are being implemented on site. The audit will identify areas or gaps where further detailed technical review is warranted.

An example of the audit topics assessed by AMC for an underground mining operation, based on the Western Australian guidelines, include:

- Mine planning and design

- General operational issues

- Drilling and blasting

- Opening design

- Rock reinforcement

- Timing of rock support

- Geotechnical data

- Stope and pillar dimensions

- Stope sequencing and backfilling

- Production blasting

Results from audits can be handled in different ways. An example of an effective use of audit data is to adopt a consistent rating system to each audit standard assessed, as provided in the table below.

This rating system identifies whether the intent of the standard has been met (S2), or whether gaps have been identified (S0 or S1) that would require follow-up by the company. Results of the audits are also indicative of industry best practice (S3), or in some cases the standards were deemed not applicable (NA) to the mine.

| Compliance | Rating | Summary |

|---|---|---|

| Not compliant | S0 | Large Gap – Does not meet intent of the Standard nor is there any evidence of progress towards meeting the intent of the Standard |

| Partial compliance | S1 | Small Gap – Does not meet intent of the Standard but there is evidence of progress towards meeting the intent of the Standard |

| Fully compliant | S2 | Meets intent of the Standard |

| Best practice | S3 | Meets intent of the Standard and is considered best practice |

| Not applicable | NA | Not applicable |

A scoring system can then be applied to the results of the audit as follows:

Compliant (S2 or S3). Meets the intent of the Standard or best practice. Possible room for improvement. Score = 2 points.

Partially Compliant (S1). Does not meet the intent of the Standard, but there is evidence of progress. Indicates that systems are in place, but not adequately acted upon. Work will be required in order to meet the intent of the Standard. Score = 1 point.

Not Compliant (S0). Does not meet the intent of the Standard, and there is no evidence of progress. Systems have not been put in place, suggesting that particular aspects have been overlooked. Will require the establishment of systems as well as adequate follow up in order to meet the intent of the Standard. Score = 0 points.

A total compliance score is then calculated for each Standard audited to provide a relative indication of the level of compliance. This score can be used to track the progress of audit compliance from year to year, as well as between different mine operations. Using the points system and standard ratings, the compliance score is calculated as follows:

Compliance Score(%)= (S0·0+S1·1+S2·2+S3·2)/(Sum·2)

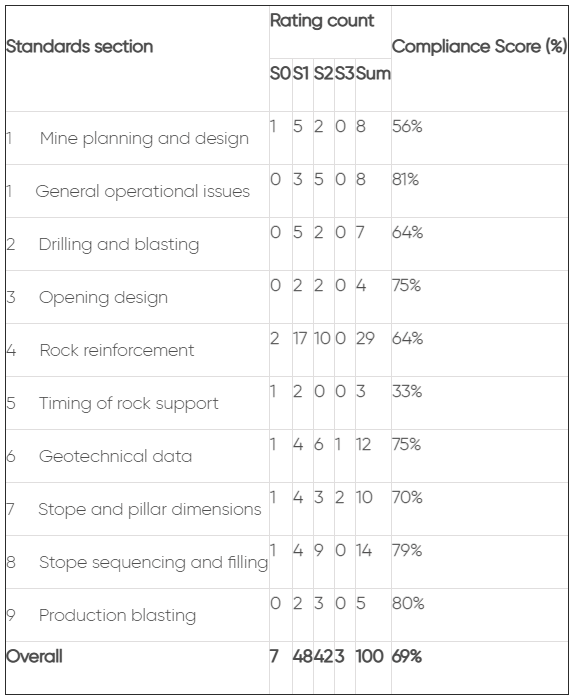

An example of the audit scorecard is summarized in the table below.

Mine X had an overall score of 69%, with individual scores by standard section ranging between 33% and 81%. The results of the audit have identified that the mine is doing a number of things well, however gaps have been identified. Detailed discussion of these gaps and room-for-improvement guidance can then be provided.

Such procedures can be applied to both open-pit and underground mining operations within a company and can subsequently identify where company standards are not being implemented or met. Conversely they can also indicate where compliance and good management is being applied to geotechnical design.

The audit results can also be benchmarked and compared with results from other mines, either in their own jurisdiction, or globally.

- NSW Department of Primary Industries, Mine ground control management plan audit tool, underground metalliferous mines, September 2008.

- Government of Western Australia Department of Mines and Petroleum, Guide to open pit geotechnical considerations – HIF audit guideline, 2009

- Government of Western Australia Department of Mines and Petroleum, Geotechnical considerations underground – HIF audit guideline 2003

For more information of to discuss this article further, please contact your closest AMC office.

Will Pitman

Vadim Louchnikov

Subscribe for the latest news & events

Contact Details

Useful Links

News & Insights